Agco MT700/MT800

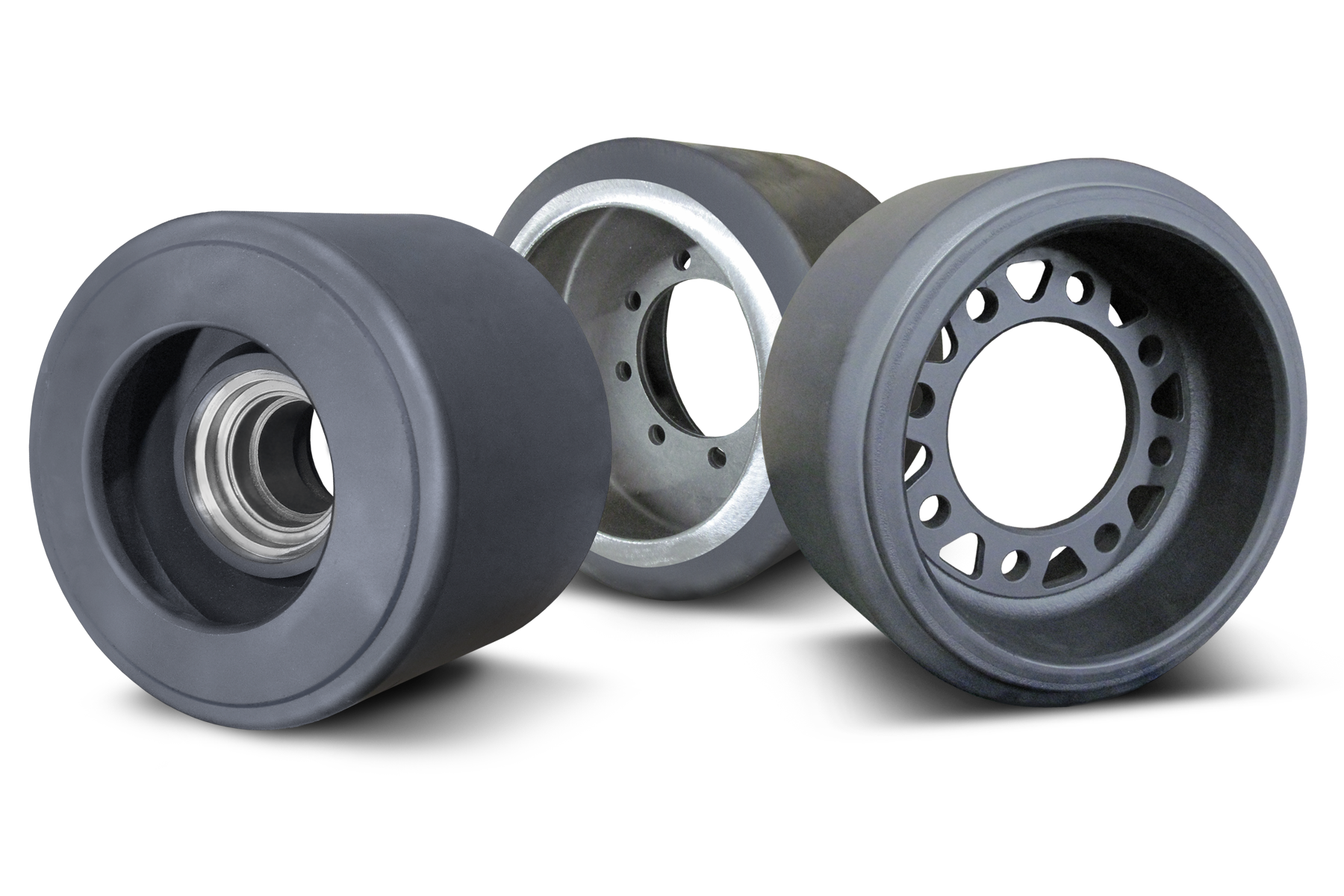

New Polyurethane Mid Roller

OEM Part# 1R-1241, 502932D1

Camso Part# 4W-0020

Superior Part# AJ02-516-MO

8 Bolts, 8.5" Wide, 14" Tall, 5.25 Pilot Hole

Shipping: Item ships out in 1 to 3 business days. Transit time can take 7 business days depending on

destination.

Fits the following Agco MT700 Model Tractors with 25" and wider tracks:

MT735, MT745, MT745B, MT745C, MT755, MT755B, MT755C, MT755D, MT755E, MT765, MT765B, MT765C, MT765D, MT765E, MT775,

Fits the following Agco MT800 Model Tractors with 27.5" and wider tracks:

MT835, MT835B, MT835C, MT845, MT845B, MT845C, MT845E, MT855, MT855B, MT855C, MT855E, MT865, MT865B, MT865C, MT865E, MT875B, MT875C, MT875E

Core Charge:

A $200 Core charge is required and added to the initial cost of the Mid Roller. The core charge will be

credited back to your account or credit card when the core/cores have been returned to the factory

(Superior) and inspected for quality. Please see Wheel

Reusability Guidelines for acceptable cores.

Site Proven Performance

Tested on the same tractor, pulling dual pan scrapers

AgriTraxx® Midrollers

After 3000 hours of pan scraping - like new with no track damage

Rubber Midrollers

After only 347 hours of pan scraping - visible excessive damage and uneven wear. Wheels have to be replaced to

prevent further track damage.

AgriTraxx® Midrollers

Thermal image showing polyurethane's highest temperature at 117.0 ºF, this lower temperature extends both to

rubber track and wheel wear-life.

Rubber Midrollers

Thermal image recorded in the same usage interval as in AgriTraxx

® Midrollers, indicating rubber’s

highest temperature at 161.1 ºF.

- No Bond Failures Guaranteed - Proprietary bonding technology that resists heat and

shear force to prevent debonding

- Longest Wear-life - Polyurethane compound engineered to generate less heat, reduce

chunking, and provide the highest cut & tear resistance

- Resist the Elements - Unlike rubber, AgriTraxx® Midrollers polyurethane is resistant to

Oils, UV, Weak Acids, Diesel Fuel, Moisture and more

- Extend Rubber Track Life - Lower operating temperatures reduce rubber track

deterioration. Tough polyurethane will not capture debris and score the track.

General guidelines for Midroller replacement

- More than 1/3 of the total rubber is missing around the entire midroller

- All the rubber is missing at any point all the way across the midroller

- Any flat spots are seen which may indicate midroller stopped turning

Note: you should always change midrollers & idlers in pairs to promote equal down pressure from the axle to the track.

Preventive maintenance

-

Check the condition of the midroller seals. Look for any wet areas that indicate a leaking seal. We recommend using Kile Clear View Caps as they assist you by giving operators the ability to view and maintain proper oil levels.

-

Check condition of midroller rubber. Worn or

midrollers in poor condition can damage the track if not replaced in a timely fashion.

Wheel Remanufacturing Service:

Want to significantly reduce the cost of replacing mid-rollers & idlers?

Contact D & J Farm Supply to make arrangements to have your worn midrollers and idlers sent in to be

reconditioned with high performance polyurethane.

Once the wheels are received, they will be stripped of all the old rubber compound and the rims will be

cleaned and prepaired for the retreading process.

The cleanned wheels will then be retreaded with Agritraxx® high performance polyurethane and shipped back

for installation.

Turnaround time can be as little as 6 weeks but could take as long as a few months.

Wheel Reusability Guidelines:

Wheels that are cracked or damaged will Not be accepted.

Flat Spots & Mud Removal

If flat spot wear is limited to the coating, core will be accepted.

If wear has damaged the steel, core will not be accepted

Wheels that are covered or filled

with mud and other debris must first

be cleaned. Cores do not have to

be washed clean but must have

majority of mud, dirt, and debris

removed.

Cores that are covered or

filled with mud and debris will not be

accepted

Chipping / Chunking

Coating loss, Chipping / Chunking are accepted forms of good cores.